Control of Processes

|

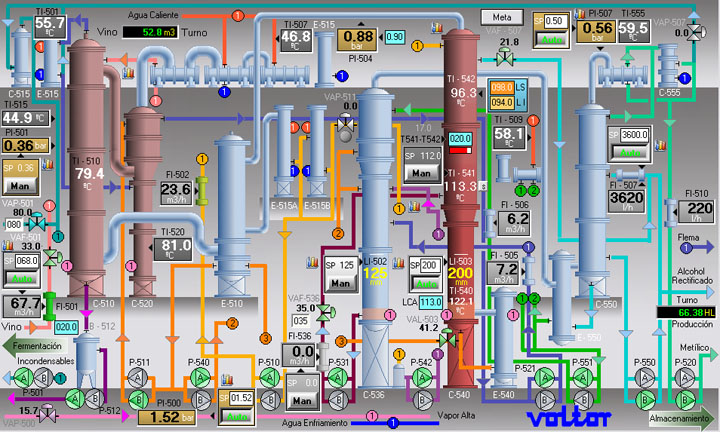

| Synoptic of Alcohol's plant of distillation ALFICSA |

The engineering in the control of processes begins as from the request of the customer of the solution of plant automation or specific equipment.

With an inspection in situ you determine the quantity of signals of Input/Output, Analogical and Digital and the distribution of the same in the area that the existent reach of the project and the loops of control.

With collection of information comes to the calculation necessary Hardware's quantity and your distribution in plant determining the quantity and type is:

Knowing the structure of control, they calculate the quantity of necessary closets and your distribution in plant defining the quantity and types.

Definition of the composition in Hardware and Software of the supervisory Job and Control.

Programming of the PLC according to the technological requests of the project and the logic of functioning of plant or equipment.

Creation in the Software of Control and Supervision of:

Startup and checking of the drawn objectives, doing the pertinent adjustments, the project does not finished until received the letter of approval for part of the customer.

Equipment to Order

|

| Thermic interchange multitubular, double- head type for the industry of oil. PROYECTOS INDUSTRIALES FAPREIN, S.L. MADRID ESPAÑA |

The equipment to order differs from the rest that they are not serialized productions, because it is a specific and particular production, Either for his dimensions, function, materials that use, no standards specification, etc.

They begin the Engineering with the elaboration of a preliminary design for your construction as from the designing bases agreed on with the customer and the Engineering develops.

To open a file with the standards and certifications of quality necessary that include:

They should include to be necessary the instructions of unloading, unpacking, assembly and startup properly documented.

Engineering activity concludes with equipment production. Once sent and placed in the final destination, of being once the Technical Assistance with the supervision of the procedures that was agree on and protocols of startup.

Calculation of Capabilities

|

| Washing machines of mineral MOA-NICKEL S.A |

The capabilities calculation engineering happens when it is necessary to accomplish a manufacture of a specific and particular plant, nonstandard for his dimensions, technological principles, and the job of materials and design of reliable components, of high efficiency with factors of services adapted for the work to realize, high efficiency with factors of services adapted for the work to realize. As well as we considerations to have in account for the assembly and the facilities of maintenance and manipulation of the aggregates during the programmed maintenances.

With these premises, develop a basic engineering or technical ante-project, base for the economical proposal, and right after being approved, the general diagram of the installation with all the specifications gathered in the designing bases proceeds to come true; Characteristics of the driving, technological parameters of operation, systems of mechanical closings, driving, mechanical protection and security, materials and protections. The dimensional fulfillment of the design and installation; Approve and formalizing the aforementioned documentation, for the construction of the equipment in total interaction with the customer's engineering.

The customer has the possibility of visiting to workshops associated with Voltor for the execution of the works; and checking the correct interpretation of the constructive requests requested by the customer; the protocol elaborated for each aggregate just like the nondestructive tests. With the final proofs so much in vacuum or with load; the coating conclusion and manipulation, etc.

At later time with the final delivery of the equipment’s, the technical documentation (descriptive memory, general diagrams, list of parts, recommended spare parts) and the startup satisfactory starting, after of approval and conformity the supplying contract are elaborated.